-

machine de soudure de maille de barrière

-

machine soudée de grillage

-

machine de soudure automatique de maille

-

renforcement de la machine de soudure de maille

-

machine de maille de gabion

-

Maille de panier de Gabion

-

Fil Mesh Machines

-

machine de barbelé de rasoir

-

Machine augmentée en métal

-

Machine de tréfilage

-

machine perforée en métal

-

M. Gurami Gureshidzesucrerie mon bon ami, fournisseur honnête.

M. Gurami Gureshidzesucrerie mon bon ami, fournisseur honnête. -

M. MIKOVOUS ÊTES BON MAINTENANT ET VOTRE SUCRERIE STABLE D'AFFAIRES.

M. MIKOVOUS ÊTES BON MAINTENANT ET VOTRE SUCRERIE STABLE D'AFFAIRES.

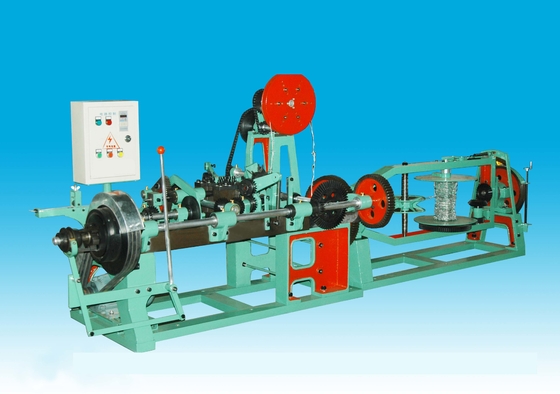

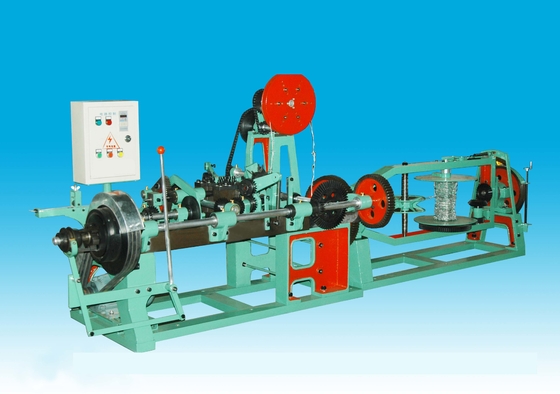

3-5 Twist Barbed Wire Machine Convenient Operation Electronic Counting Control

| Lieu d'origine | Hebei, Chine |

|---|---|

| Nom de marque | DIAOZHUO |

| Certification | CE ISO9001 |

| Numéro de modèle | DZ-CSA DZ-SCB DA-CSC |

| Quantité de commande min | 1set |

| Prix | variable |

| Détails d'emballage | woodencase et sachets en plastique |

| Délai de livraison | 20-30 jours |

| Conditions de paiement | L/C, D/P, T/T, Western Union, MoneyGram |

| Capacité d'approvisionnement | 20 ensembles par mois |

Contactez-moi pour des aperçus gratuits et des bons.

WhatsApp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Si vous avez n'importe quel souci, nous fournissons l'aide en ligne de 24 heures.

x| ingénieur | entretenez les machines d'outre-mer | torsion | Simple |

|---|---|---|---|

| Matériel | fil galvanisé à chaud | Diamètre de fil | 2.2-3mm |

| capcity | 40kg/hour | Moteur | 2.2Kw |

| Mettre en évidence | expanded metal sheet making machine,high speed expanded metal machine |

||

Convenient Operation Electronic Counting Control 3-5 Twist Barbed Wire Machine

The strands are fed intermittently by a fixed-length wire feeding mechanism. The eccentric distance on the eccentric disc can be adjusted to achieve your desired stab distance according to user requirements. The stab distance specifications are 50, 80, 100 (mm) (special specifications can be negotiated. Do), enter the winding head through the squashing device. The fan-shaped gear drives the gear shaft to return around the wire head, rotate counterclockwise, and wind the barbed wire regularly on the flattened strand position. After one round of rotation, the cam pushes the lever to raise the movable knife holder and cut the barbed wire. The stabbing action ends. The single-stranded barbed wire passes under the sliding gear, on the gliding wheel, on the wire discharging wheel, and on the take-up mandrel. The take-up sprocket is driven by the main drive sprocket to take up the wire in parallel through friction transmission.

Barbed wire is made of electric galvanized barbed wire wrapped around the main wire and twisted to protect and isolate it. The twisting method is divided into single twisting and double twisting. The construction methods include direct installation method and spiral cross method. Uses: for industrial, agricultural, animal husbandry, highway, forest farm protection.

Technical parameter of barbed wire making machine

![]()